We are a professional paper tube manufacturer from China, we can customize any specification and requirement you need. The following is for the paper tube surface processing technology.

Offset printing

Offset printing is a classic and basic way of printing in modern printing. To date, offset printing is the leader in the printing services market due to its high quality, economy, and productivity. It is widely used in its machines, devices, technologies, all the achievements of modern science. we have installed a 5+1-color sheet-fed offset printing machine with the lacquering function of the recognized world leader – the German concern Heidelberg.

In our production, we can produce industrial batches of products with maximum efficiency and perfect quality in the shortest possible time.

B2 + 745×530 mm printing equipment is able to print full-color works at the same time using additional special pontoon inks while covering sheets of water-dispersed varnish at the same time.

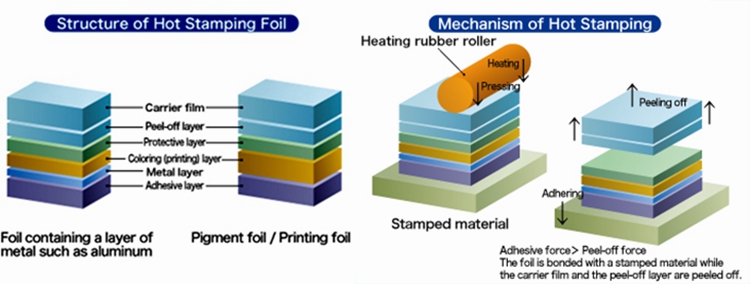

Hot stamping foil

Hot stamping foil is material for application to the surface of Printing paper, plastic, wood, and metal as well as painted surfaces by hot stamping. Cardboard paper tube is widely used in cosmetics packaging, gift packaging, wig packaging tube, essential oil packaging, lip gloss packaging, and daily necessities and clothing packaging, and more applications.

We provide hot stamping foils of many types, designs, and colors according to the purpose.

Hot Stamping Foil list

Gold, silver, blue, pink and various other metallic colors are available.

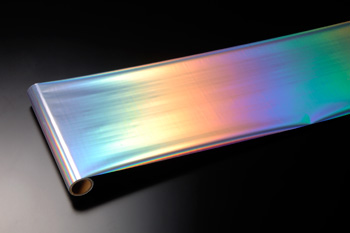

Hologram Foil (Hot Stamping Foil)

It has a particular kind of gloss with polarization, giving your products a luxurious texture.

It is difficult to make a similar product, so it can be used to prevent counterfeit products.

Multi-color Stamping Foil

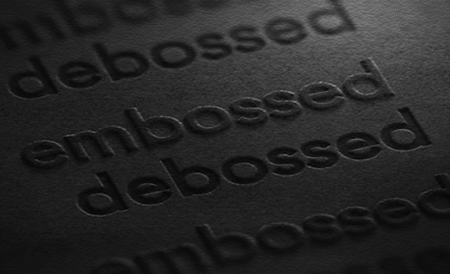

Embossing and debossing

Embossing

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials. An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material (but might protrude somewhat on the reverse, backside).

Pressure: the intensity of the impact on the weight of the stock being embossed.

Heat: the ability to maintain a consistent heat level for the best impression.

Die depth: the client’s artwork or the engraver’s efforts will initially determine the die depth, however, if by looking at the artwork it appears that an adjustment of the die depth may be necessary, the die may need to be retooled to achieve a greater depth. Most types of paper can be embossed, and size is not normally a consideration. Embossing without ink, so that the image is raised but not colored, is called “blind embossing”. Embossing used in conjunction with ink, so that the raised area is colored, is called “color register embossing”. Embossing used in conjunction with foil stamping is called “combination stamping” or “combo stamping”.

Debossing

UV varnish

Matte and glossy surface

Glossy paper is shinier—this makes the color in your images “pop” on the sheet. The extra shine works well on print files with heavy color coverage, especially photographs and big graphics. This effect also gives the color on the prints look like they have higher contrast. Matte paper has a more muted feel to it